Purvaj engineers' offers very distinct lines of press brakes to provide all your bending and forming requirements. Combine this greater selection with our vast range of machine options.

A solution perfectly engineered to your applications.

Purvaj Press Brakes are highly productive, accurate, and economical. Through advanced design and construction, purvaj offers quality Hydraulic Press Brakes that incorporate conventional ram design.

All purvaj Press Brakes are easy to operate and provide simplified and easily accessible controls for optimum operator efficiency and output.

Request A QuoteThe all-steel-structure Of Purvaj Press Brakes consists Of side frames, ram, I-Beam type table and pair of levers manufactured from ultrasonically tested steel plates.

All sections are designed to give minimum deflections and maximum rigidity as per international standards.

Pair of hydraulic cylinders are synchronized by heavy duty torsion tube welded by the leavers, this offers complete parallelism between them and working table surfaces.

Purvaj engineering/manufacturing process assure unrivalled precision and durability for year of trouble free service.

A Purvaj Engineers combine great selection with great pricing for superb value. The standard purvaj package offers repeat accuracies as well as numerous features and option tailored for sheet metal and fabrication application.

Reliable Hydraulic System :

Reliable Hydraulic System :

International reputation hydraulics components Specially designed manifolds gives smoth noiseless & jerkless function.

Overload Protection system :Overloading and damage to the press brake and tooling prevented by quick response relief valve system.

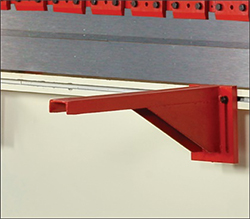

Front Sheet Support fixtures

Front Sheet Support fixtures

Heavy duty front sheet support for gauging and easire part handling

Adjustable Stroke Speed Control

Adjustable Stroke Speed Control

Stoke Length Adjustment | Fast Approach, Slow Bend and Fast Return

Adjustable Stroke Speed Control

Adjustable Stroke Speed Control

The ram is accurately guided with minimal clearance in long slide ways covered with replaceable, anti-friction material. Wear adjustment can be carried out at any time to insure continued precision.

Actuating Controls

Actuating Controls

Purvaj's Press Brakes have three operational modes for operator's greater convenience and least fatigue which can be selected from the panel door mounted selector switch.

Inch cycle : This mode is used for setting bed angle depth stroke. The ram movement (up down) can be controlled at any described position from foot switches.

Auto cycle : The cycle (Approach-Pressing-Return) is continuously repeated once this cycle is selected. This mode is useful for continuous repetitive work where stroke length can be adjusted to suit the job and the operators speed and rhythm.

Easy & Quick Backgauge Setting

Easy & Quick Backgauge Setting

Manual back gague with micro setting

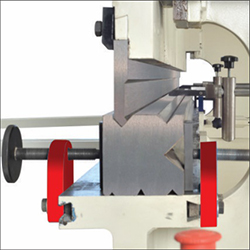

Toolings

Toolings

Auto Lubrication System

Auto Lubrication System

Centralized Lubrication system with auto control

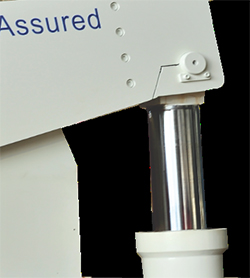

Rear Cylinder Design

Rear Cylinder Design

Rear cylinder design using mechanical advantages through lever, reduces the cylinder size which enable to use medium pressure hydraulic component and also improves stoke accuracy

Request A Quote341, GIDC Por, Ramangamdi, Por,

Vadodara, Gujarat - 391243, India.

+ 91 98257 68697

0265 - 2988697